Powder Coatings Hosokawa Micron Powder Systems

Paint offers fewer benefits than powder coat. Durability and versatility in powder coat vs paint wheels, paint cannot match the level of powder coat. You should apply a powder coat on car wheels to save money in the long run. Paint is more vulnerable to scraping and shaving. Powder coats offer better coverage.

Powder Coating Wheels Pros And Cons otomotif tips

Powder Coating Wheels Pros and Cons. Powder coating is a process that coats the wheel with a hard, durable finish.. 14 Striking American Muscle Cars with Lackluster Performance. 2024-03-09. Celebrating the 13 Greatest Motorcycle Racers in History. 2024-03-09.

The Pros and Cons of Powder Coating A Guide for CNC Machining Experts

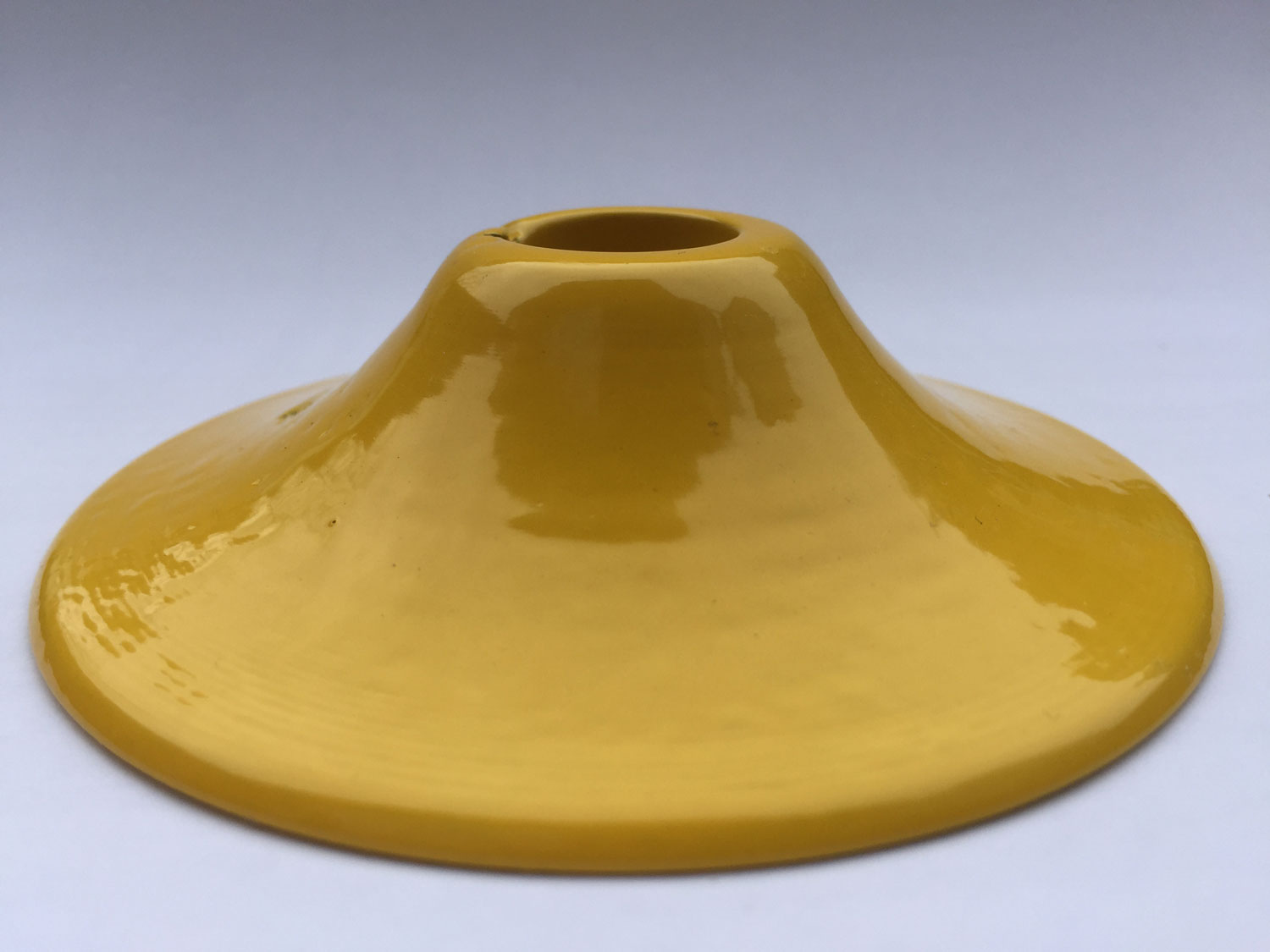

Powder coating is a process in which a thermoplastic or thermoset powder is electrostatically sprayed onto the wheel to form a barrier between the wheel's surface and its environment. The powder is then heated to over 400 degrees Fahrenheit, which causes it to melt and form a hard coating that seals and protects the underlying surface.

11 Pros and cons of Powder Coating Wheels

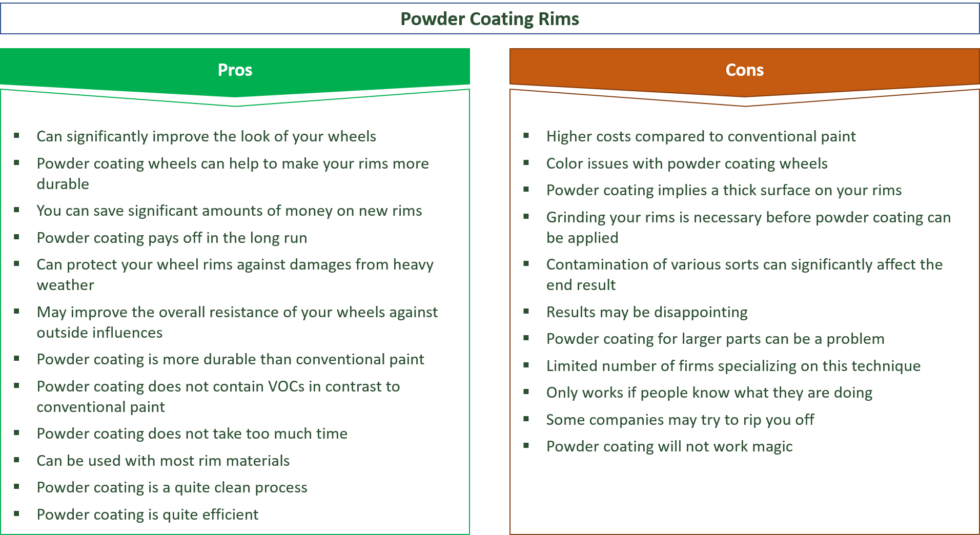

Advantages of Powder Coating Wheels. Can significantly improve the look of your wheels. Powdercoating wheels can help to make your rims more durable. You can save significant amounts of money on new rims. Powder coating pays off in the long run. Can protect your wheel rims against damages from heavy weather.

Powder Coating Wheels Pros and Cons Royal Coatings

Powder coating provides a non-porous, more durable surface protection than traditional liquid paints, ensuring that your powder-coated rims can withstand even the most extreme road conditions. 2. Longevity. Once the powder coating is applied, it may be the hardest material on the planet.

Cream vs Powder Contour The pros and cons to help you decide — Project

Powder coating wheels are more expensive than painting wheels. The cost of powder coating differs based on the coat of supplies in the market. Furthermore, other cost factors include the model of the vehicle, the size of the wheels, and the quality of the job. That said, the average cost of powder coating a four-wheel set varies from $350 - $700.

Apple iPhone 14 Pro Reviews, Pros and Cons TechSpot

Powder coating wheels provide a superior finish that is durable. It will protect your rims for many years, learn the pros and what to avoid.

Powder Coating Wheels Pros And Cons Including What to Avoid

Cons: Thinner finishes: One drawback of powder coating is that it creates a relatively thicker finish compared to spray painting. This may not be suitable for projects that require a very thin coating. Large-scale applications: Powder coating is typically more suitable for larger applications as it requires specialized equipment and an oven for.

28 Key Pros & Cons Of Powder Coating Wheels E&C

9. Powder coating is quite effective. The waste is minimal to none as compared to the traditional painting of the wheel's rim. Practically every powder particle will adhere to the rim and be much more effective than the traditional procedure. 10. Powder-coating wheels may help to prevent global warming.

Powder Coating Wheels Pros And Cons otomotif tips

Since powder coatings do not contain any solvents, they emit little to no VOCs throughout the finishing process. Some other environmental advantages of powder coatings include less carbon dioxide emissions, no hazardous waste requiring disposal, and no need for the use of a primer before the coating application.

Powder Coating — ten hand tool

Powder coating wheels has become a popular option for car enthusiasts looking to upgrade not just the aesthetics of their vehicle, but also enhance durability. The process involves applying a free-flowing, dry powder which is then cured under heat to form a skin-like layer.

Powder Coated Rims Pros & Cons Of Powder Coating The Wheels

The powder coating on the rims will create a non-porous surface that shields the wheels more than a traditional paint would create. You'll come out of some unforgiven conditions with less overall damage than you would in most other scenarios. 2. Powder coating provides your wheels and rims with better durability.

Powder Coated Rims Pros & Cons Of Powder Coating The Wheels

One major downside of powder coating wheels is the price. Since the process is more involved than simple painting, the cost to have your wheels powder coated is typically much higher than it would be for painting. However, the cost does pay for itself in the long run in terms of a superior finish and added protection for your wheels.

Powder Coated Rims Pros & Cons Of Powder Coating The Wheels

Price: While paying someone $400-$500 to powder coat a set of wheels in the color and clear coat of your choosing may sound inexpensive to some, it is completely out of the question for most people. Being that many "bargain bin" wheel manufacturers are offering entire sets of wheels at these prices, the powder coating approach is a tough sale for those looking for little more than a quick.

Powder Coating Wheels Pros And Cons Including What to Avoid

First, this material makes your tires more capable of withstanding scratches and corrosion. This service is relatively affordable, averaging around $500 for a set of powder coating wheels, which is a fairly reasonable price. Another advantage with powder coating wheels is the low environmental impact. Unlike conventional paints, powder coating.

Pros and cons of Powder coating or painting motorcycle wheels

The powder-coated surface strongly bonds with the metallic surface on your rims and it gives your rims a brand new look. Pros and Cons of Powder Coating Rims . If you are considering using other methods to improve your rims' overall appearance and durability, you'll want to know the pros and cons of powder coating first. Pros: 1.