Top 5 Best Paints for Aluminum [September 2023 Review] MetalProfy

To strip off these contaminants, you will need to apply your cleaner of choice to the powder coat. Acetone works great, and so does paint thinner. Wipe it off with a rag, and then let it dry. Step 4: Spray Rustoleum Paint on the Scuffed Powder Coat. Your powder-coated surface will be ready for paint application.

Can You Paint Over Powder Coat? ProfyPainter

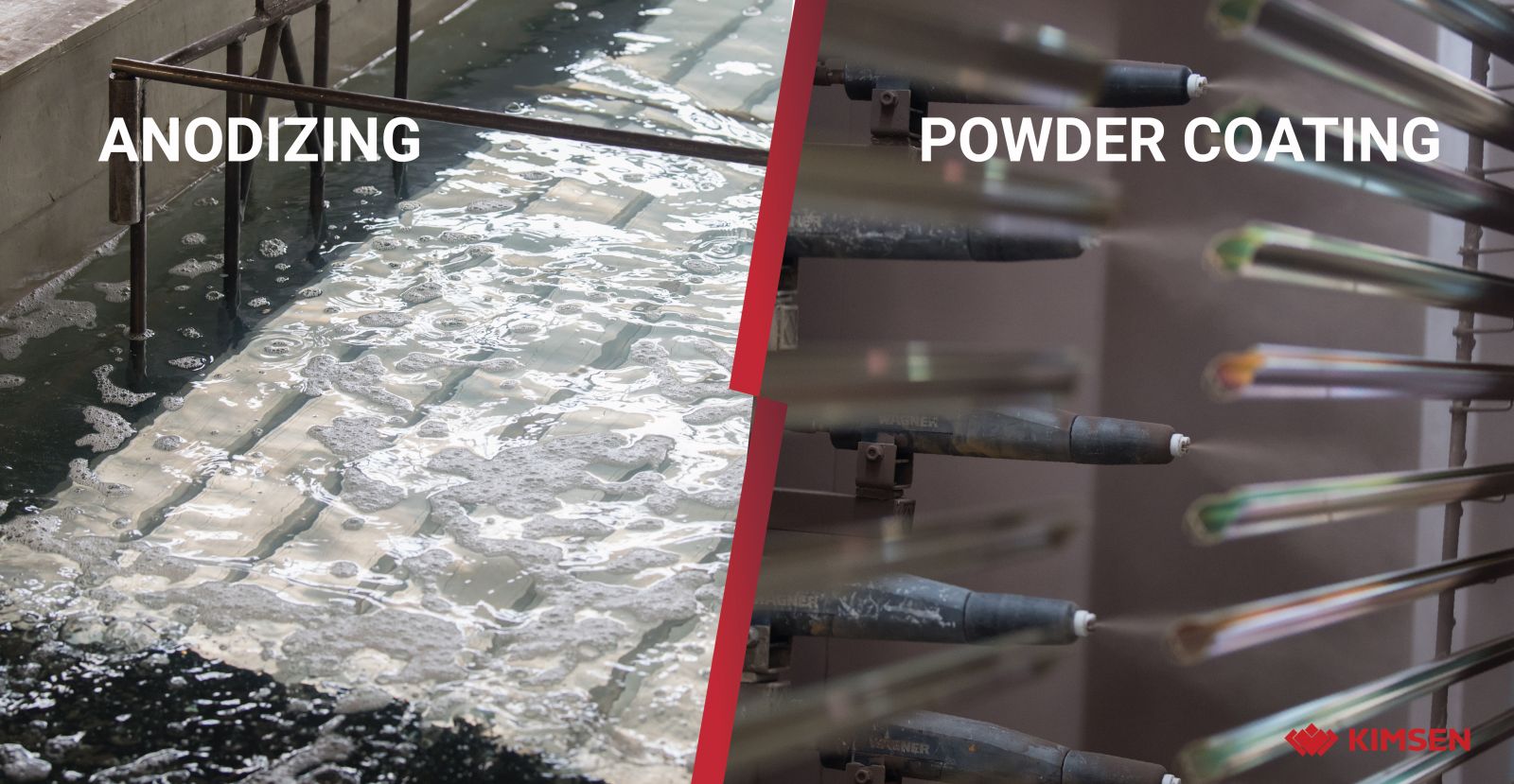

Powder coating as a finish has a lot of benefits and drawbacks which you can learn more about here. It is often chosen for its durable finish, its environmental friendliness, and lower variable cost in comparison to liquid coating. Despite its greater durability, even powder coating is susceptible to experiencing abrasions and damage over time. When scratches or abrasions occur the underlying.

Can You Paint Over Powder Coated Metal Tiny House & Small Apartment

Yes, you can paint over powder coating. Many choose to paint over their powder-coated products as a simple way to change their appearance or maintain their quality. While powder coatings are incredibly durable and resistant to wear and damage, they can still receive scratches and other imperfections over time.

How to Paint Over Powder Coating Pittsburgh Spray Equipment

In conclusion, you can paint over powder coating with proper preparation. By cleaning the surface, roughening it with sandpaper, and using a suitable primer and paint, you can achieve a smooth and durable finish. Remember to choose paints specifically designed for adhesion to powder coating, like epoxy paint. With these steps and considerations.

Industrial Spray Painting or Powder Coating? APT Spray Painting

In such cases, painting over the existing powder coating can provide a cost-effective and customizable solution. To achieve a successful and long-lasting result, it's crucial to follow the proper steps and techniques when painting over powder coated metal.. You can use a brush, roller, or spray gun, depending on the size and complexity of.

How To Spray Paint ProperlyFull Tutorial YouTube

If the coating is completely intact, the technician will lightly sand it. This creates a rougher surface to which the paint can adhere. If the powder coating has worn away in some places but not in others, the technician may go ahead and sand off the coating entirely. This ensures a consistent surface for the paint application.

What is Powder Coating? How it Works & When Can Use A New Way Forward

Yes, you can paint powder coatings to help repair a damaged surface. Painting a powder coat is a simple, effective way to preserve its quality or freshen up its appearance. Paint can seal chips and scratches, helping extend its performance and life span. Here are some frequently asked questions and best practices for painting over powder coatings.

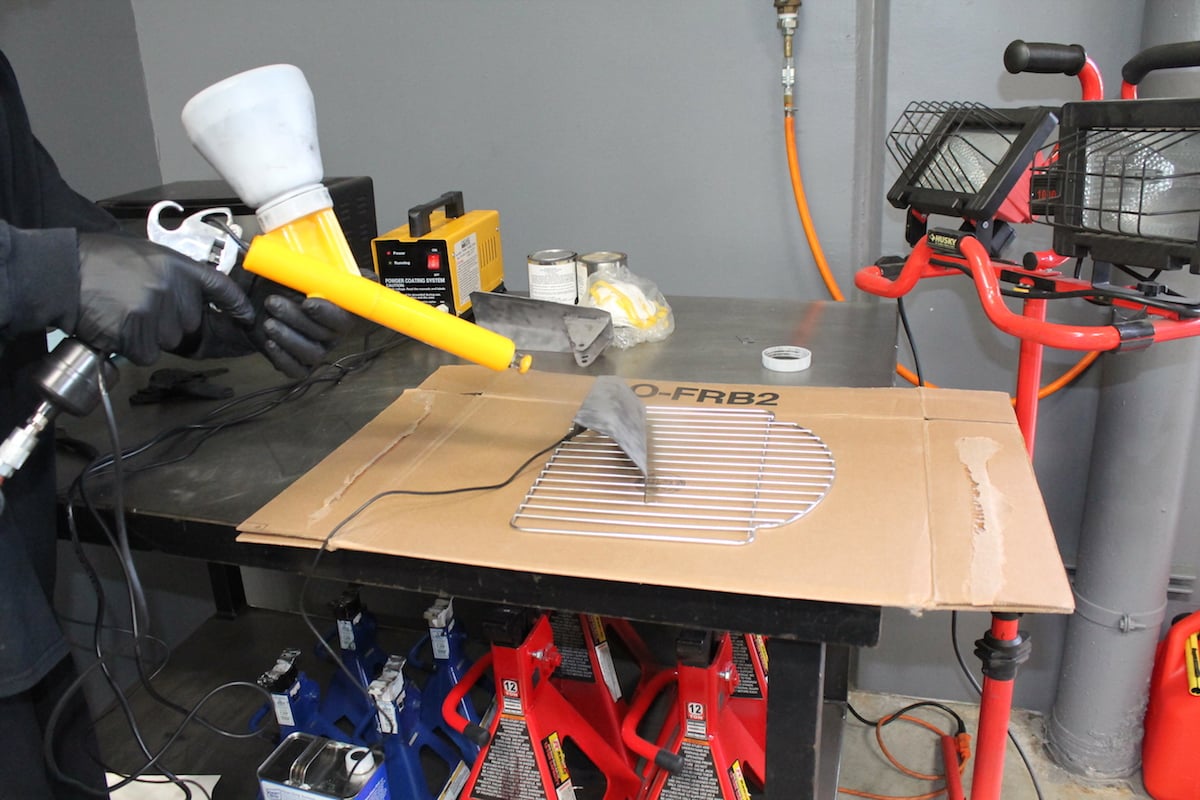

Powder Coating At Home A HowTo Guide For The Home Handyman

But if you see red rust on the metal surface, then you'll need a power sander to remove it. After the corrosion is removed, wipe away the remaining dust with a tack cloth. Step 3. Sanding the Surface. Sanding the aluminum surface will ensure the primer and paint will stick to the powder coating.

Powder Coating Electro Polish Dayton, Ohio Black Oxide, Aluminum

A top coat can be selected in a choice of colours and gloss levels appropriate for painting over powder-coated aluminium, but it is crucial to choose the right one. If a primer hasn't been used, the top layer must be selected to adhere to the primer or directly onto the aluminium. Again, a professional spray painting company will ensure that.

Anodizing vs. Powder Coat How to Choose the Right Aluminum Finish

Step 2: Primer Application. Apply a high-quality primer after preparing the surface (metal). Ensure compatibility with both the existing powder coating and the chosen paint. The primer enhances adhesion and provides a smooth base for the paint. For priming over powder coat, consider the following options: 1. Zinsser Bulls Eye 1-2-3 Primer Sealer:

10 Best Spray Paint for Use on Metal Surfaces (2022)

Use a fine grade abrasive paper. Normally, powder coating has a slick surface which does not allow paint to stick. Sanding it down carefully will enable you to paint on it effectively. Wipe down the area you will be painting with an appropriate solvent cleaner. Finally, rinse it down with warm water, then allow it to dry.

Aluminium Powder Coating — GOSS Outdoor

Luckily, Zinsser have developed products that are cost-effective and quick to apply and dry, simply painting over a suitably prepared powder coating to seal and prime the surface before finishing from a selection of 4,000 colours. Step 1. Surface Preparation. Clean down the surface and ensure it is dry and free from anything that could.

Can You Paint Over Powder Coat? ProfyPainter

Painting your powder coated windows is an easy way to revitalise your home and add extra character to your space.We'll show you how to paint over powder coat.

Automotive Paint Vs Powder Coat

How to Paint over Powder Coated Aluminium. 1. Clean the Substrate. Any dirt or grease on the metal surface will prevent the subsequent coating from clinging, so all contaminates and debris must be removed. The aluminium can be hand washed using a soft brush or jet washed if the aluminium is extremely dirty.

Powder Coating Colors Everything You Need to Know for Home Use

The short answer is yes, you can paint over powder coated steel. Powder coating is a type of paint, so it will adhere to the metal underneath and provide a good surface for new paint to adhere to. However, there are a few things you should keep in mind before painting over powder coating.

Aluminum profiles coated with colorful powder coating. FORREST

Answer. Powder coatings are an excellent paint base. All paints will adhere to polyester and epoxy powder coated surfaces provided there are no slip agents on their surfaces (added to paint and powder formulation to increase mar resistance). They can act as release agents and painting over them would be like painting over mold release.