Removing Chrome With Acid Evilution

Once the chrome has been removed, take out the object from the container and thoroughly rinse it using soap and clean water. Leave the object to dry completely. Chemical removal of chrome from plastic materials is not feasible due to the highly corrosive nature of many chemicals, especially at higher concentrations.

How To Remove Water Spots From Chrome, Aluminum & Stainless Steel

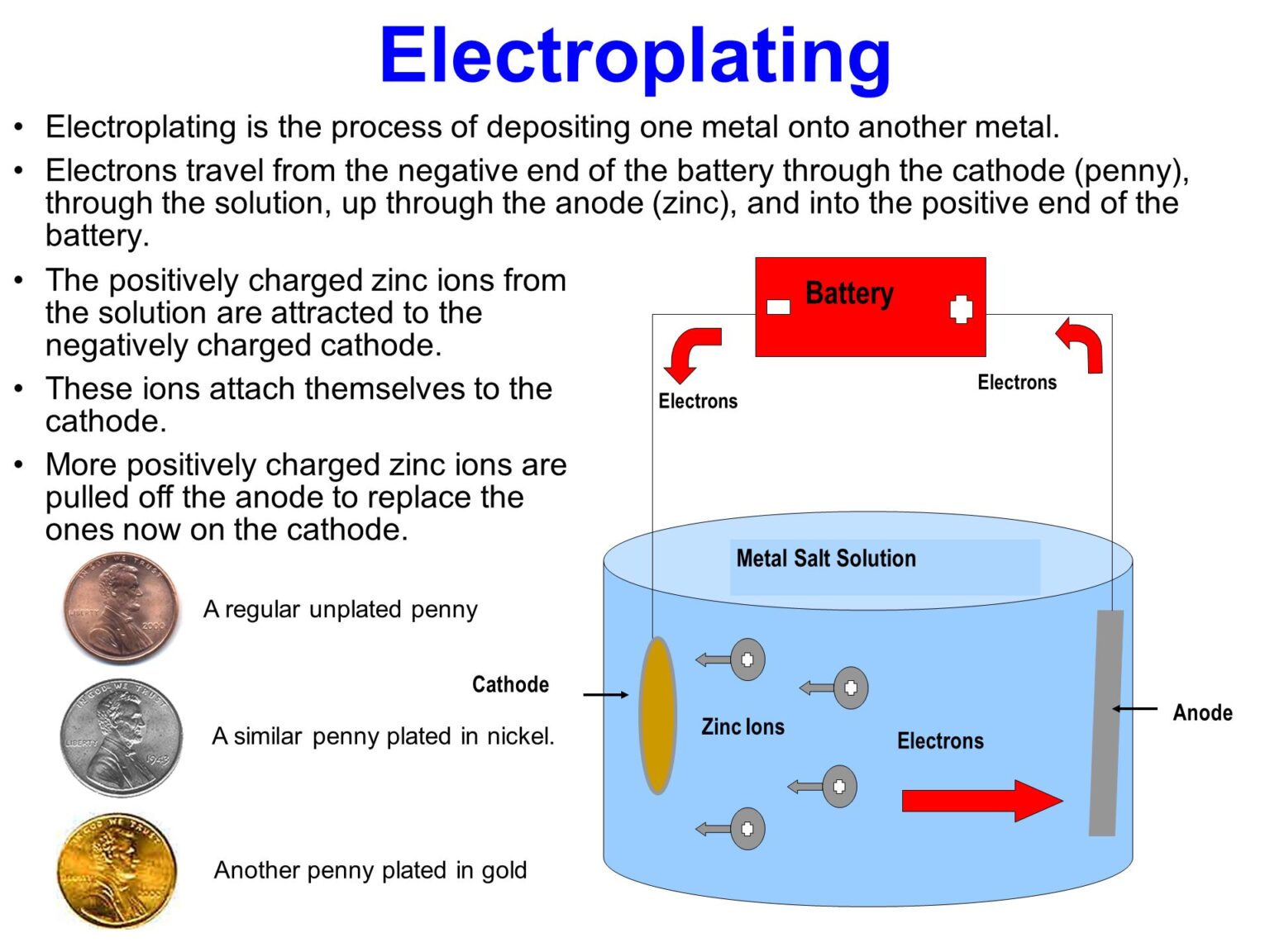

Chrome plating is a process that involves electroplating a thin layer of chromium onto a metal object. Chrome plating has various purposes, such as improving the appearance, hardness, corrosion resistance, and friction of the object. Chrome plating can be done using two different methods: hexavalent chromium and trivalent chromium.

How To Remove Chrome From Plastic (Without Destroying The Plastic

Dec 30, 2020. #2. Chrome plating is usually a thin layer of chrome over a layer of nickel which in turn us usually over a layer of copper or zinc. You can use muratic acid (dilute hydrochoric acid) to remove chrome, but that won't remove the nickel and copper. If you just want to paint it, I would just use a wire wheel and knock off all the.

Hard Chrome Plating Industrial Hard Chrome Plating Chrome Plating

September 04, 2015 05:14. There are two different ways to remove chrome from wheels. Chemical stripping (de-chroming) We can chemically strip the alloy wheels, which some people may suggest, but there are two issues here. The first being that chrome is very difficult to remove and the chemical process often leaves patchy areas where the chrome.

How to Remove Chrome Plating from Stainless Steel An Overview

Ultrasonic cleaners have a reputation for use for relatively small materials that resist other forms of chrome removal techniques. 2. Chemical Solutions. In developing chrome plating, one needs to trigger chemical reactions with an electric current. Conversely, one can remove chrome plating with certain chemicals.

3 Ways to Remove Chrome Plating wikiHow

Pour the Liquid Plumr into one of the glass bowls. Do this slowly to avoid splashes or spills. Carefully place the chrome-plated parts in the bowl. If you don't have a big enough vessel to hold all the parts, you may have to strip the chrome in batches. Use tweezers to fully submerge the chrome-plated parts in the Liquid Plumr.

How To Remove Chrome From Plastic Model Car Parts YouTube

Here's how: a. Gather your materials - You'll need a chemical stripper designed for chrome plating removal, rubber gloves, eye protection, and a well-ventilated area. b. Apply the chemical stripper - Follow the manufacturer's instructions for application, usually by brushing onto the surface or immersing the item in a solution. c.

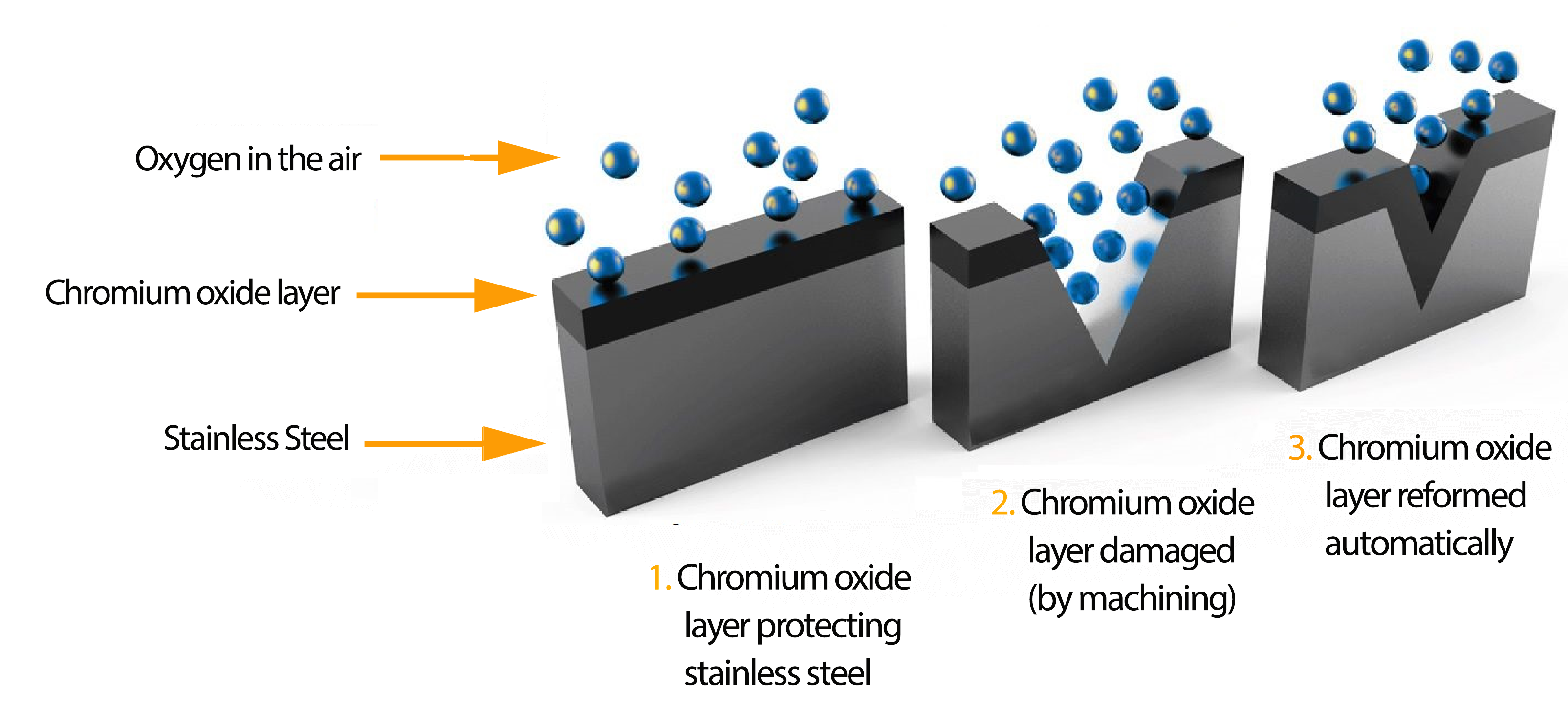

Guide to Passivation Treatments [Specific Content]

Lastly, you will need standard tools like a wire brush, sandpaper, and steel wool. Step 2: Prepare the Steel. Once you have all your materials ready, use the wire brush or sandpaper to rough up the surface of the steel so that the chrome is exposed and easier to remove. Make sure you wear your protective gear before proceeding with this step!

4 Ways to Remove Rust from Chrome wikiHow

Stripping, Polishing, Chrome plating - the Chrome Restoration process. Chrome restoration for any chrome plated car or motorcycle METAL part means 3 main steps - Strip, polish, chrome. Stripping can involve electric or chemical stripping, depending on the substrate material. Each layer of old plating may require a different solution to.

Spray on Chrome wetRemove Chrome solutionน้ำยาลอกโครเมี่ยม YouTube

Alternatively, purchase a pre-mixed acid solution of sufficient concentration. Submerge the chrome-plated object in the solution until chrome strips off. Wash the object thoroughly in soap and water, and rinse before drying. 2. Use sodium hydroxide (lye) to strip chrome from ferrous metals and carbon steel.

Automotive Paint Stripping The Complete PRO/ CONS Guide

Start by applying acetone or paint remover onto a rag and rubbing it over the area where the chrome has been scraped off. Let it sit for 5 minutes before wiping away any residue with another clean cloth soaked in warm water and dish soap (make sure you rinse after). If stubborn residue is left behind after this step, apply paint remover.

How To Quickly Strip Paint Chemically Down To Metal Stripper

To remove or strip chrome plating from metal, either use mechanical abrasion/grinding or it can be done using a reverse electrolysis approach, in which the part to be de-plated is made the ANODE in an electrolytic cell using a strongly caustic electrolyte, which ionizes and dissolves the plated metals.

Electrolysis Process Diagram

Once you have prepped the area, use steel wool to start removing loose plating from the surface of your brass item. Be careful not to apply too much pressure; use light strokes and take care not to scratch the underlying brass surface. If there are still patches of chrome plating that won't come off easily with steel wool alone, move on to.

4 Ways to Remove Rust from Chrome wikiHow

To remove chrome, 30 to 40% concentration of the acid solution will suffice. Prepare a mixture of 1/3 part of muriatic acid with 1 part of water to make a 30% acid solution in a heavy-duty bucket of plastic. You can also buy pre-mixed acid solution as well. Now, you need to submerge chrome plated metal objects in that solution.

Chrome Stripping, Dechroming, Remove Chrome Chrome Fix Chrome

Step 3: Scrub Away Residue. When time is up, take a scrubbing pad or brush and remove the remaining residue from your project's surface. Be sure not to apply too much pressure, as this could damage or warp your project's surface. If necessary, reapply more chemical remover if stubborn patches of chrome plating remain after you have finished.

How To Remove Rust From Chrome Cheap And Easy YouTube

Preparation. The first step in chrome plating is preparation, which is crucial for a successful outcome. The object to be plated must be meticulously cleaned to remove all dirt, grease, and any previous coatings. This often involves chemical and physical cleaning processes, including degreasing, stripping, and sometimes sandblasting.