Bespoke, green and highperformance The rise of 3D printed shoes

Finished shoes next to ZMorph multitool 3D printer (Source: Gronowicz & Motylinska) Both 1.75 mm Plastic Extruder and DUAL PRO toolhead for ZMorph multitool 3D printer were used to materialize this project. Single material printing proved to be successful for various types of flex filaments. Two-material extruder printed more intricate objects.

Effective shoe manufacturing with 3D printing Covestro

Looking for 3D printable models for shoes and sneakers? We offer a variety of options including STL files and 3D print models. Use your 3D printer to create your own unique designs with our 3D printing files. Explore our collection now to get started on your next project! Advertising View all designs of Shoes subcategory

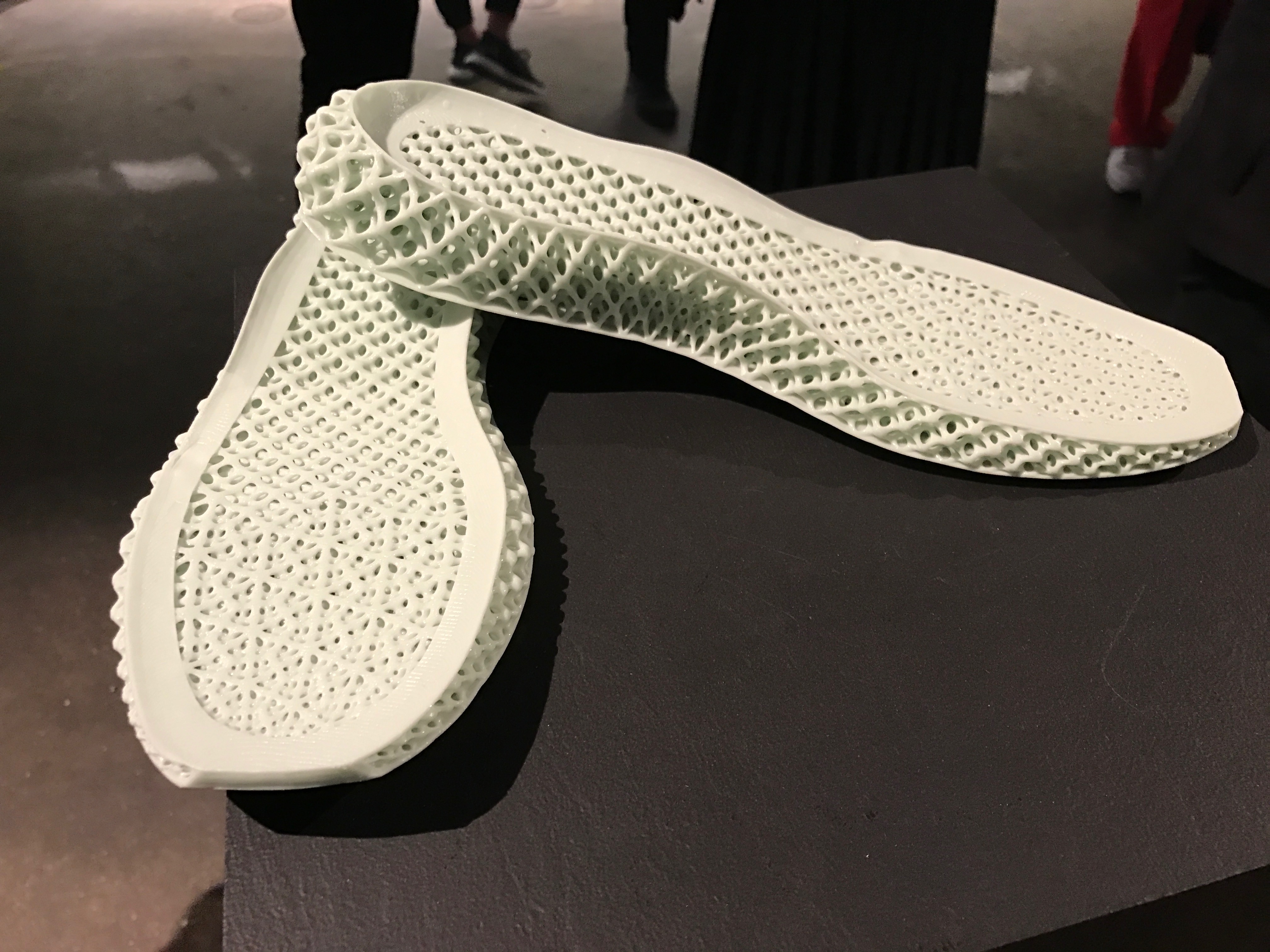

Adidas and Materialise Propose Futurecraft 3D 3D Printed Shoes « Fabbaloo

Download files and build them with your 3D printer, laser cutter, or CNC. Thingiverse is a universe of things.

64 Strangest & Catchiest 3D Printed Shoes

The usual timing for printing 3D print on demand shoes may range from 5-30 hours depending on the shoe size, type, and design of the shoes. If your shoe is open like a wedge, high heel, or flip flop, the printer will do the task in less than 8 hours. However, if the shoe is close to a moccasin, sneaker, boot, or jogger, the printer may.

The Cryptide A Fully 3D Printed Shoe Inspired by Mythical Beasts

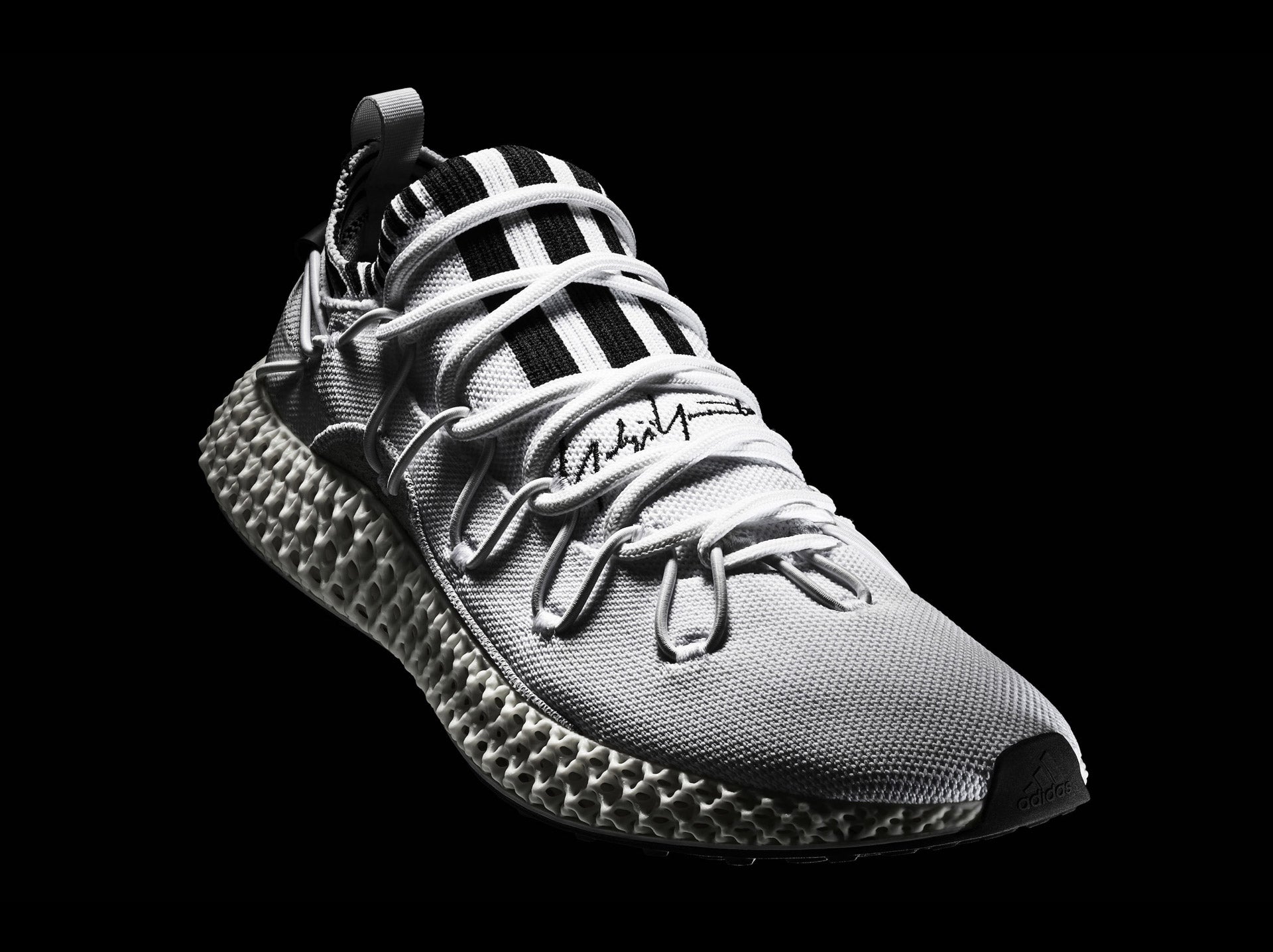

The Nami Zellerfeld 3D-printed shoe collaboration with Finn Rush-Taylor. Shoemakers have been flirting with 3D printing for years. The biggest names in footwear and fashion — Adidas, Nike NKE -0.

3d printed TPU Shoes 3d printed shoes, Shoe design sketches

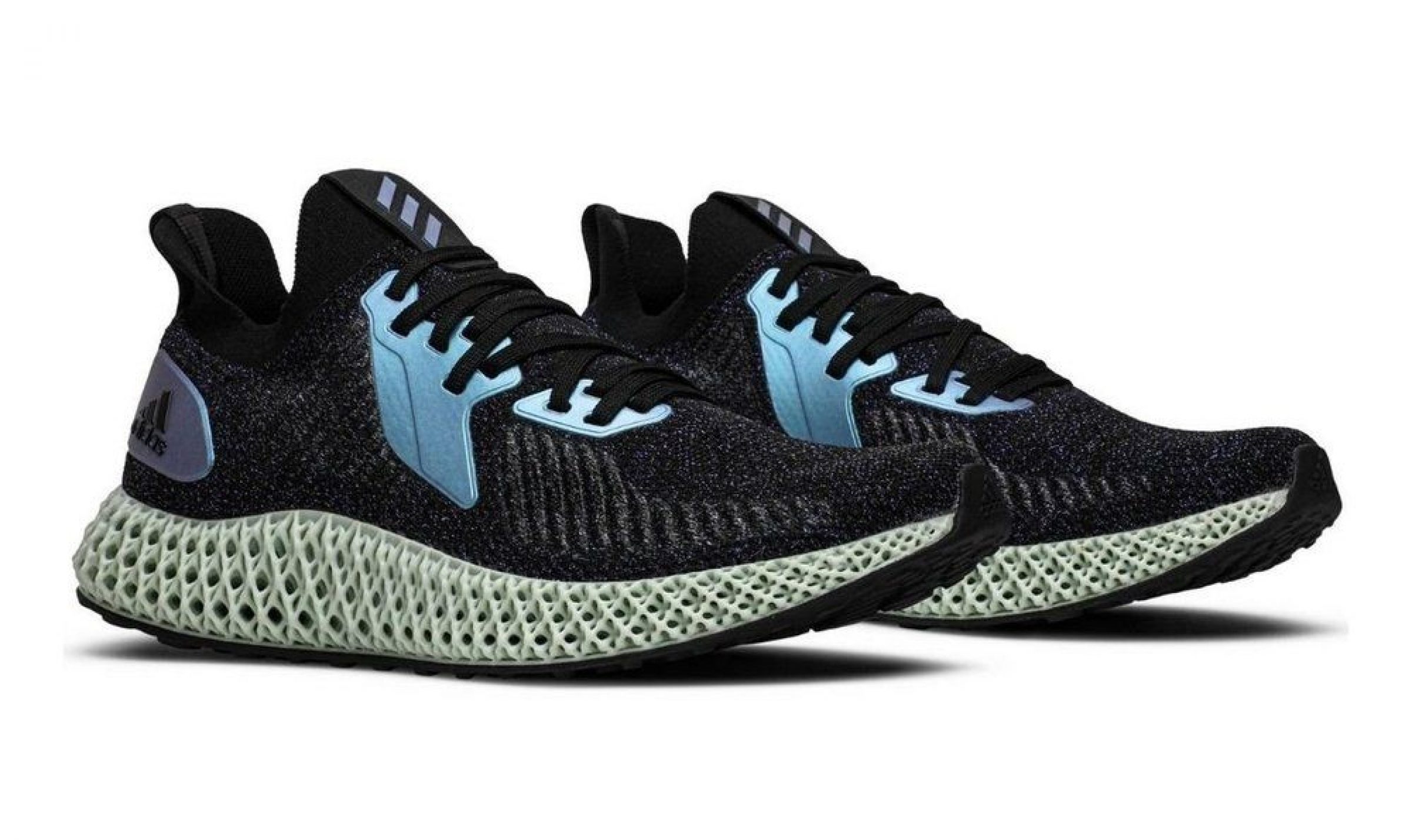

Through advances in material science, it is now possible to 3D print with polymers that are impact-resistant, wear-resistant, and weatherproof. A testament to this is the fact that big brands like Adidas, New Balance, Under Armor, and Reebok have all come up with sneakers and running shoes that have 3D printed midsoles and outsoles.

Customizable 3D Printed Shoes from Polish Students

Nike has unveiled its latest footwear innovation, the ISPA Universal, which combines 3D printing, artificial intelligence (AI) design, and eco-friendly materials. The shoe is made using an injection molding process that utilizes Bio-EVA foam derived from sugar cane, promoting sustainability.

Adidas running shoes with 3D printed midsoles push your feet forward

The 3D printing technology allows the production of complex structures that optimize shock absorption while making the shoe lighter. Since then, the American brand has been working with Formlabs and its stereolithography technology on the development of a Triple Cell platform to produce the FuelCell Echo. The shoe's midsole was 3D printed

3D printed shoes How 3D printing revolutionizes the footwear industry

The process of designing 3D printed shoes begins with a clear understanding of the shoe's style and intended purpose. This step is crucial as it directly influences the overall design, materials used, and functionality of the shoe. Here are key considerations: Type of Shoe: Determine if you are creating sneakers, sandals, heels, or another style.

This parametric 3D printed sneaker is made entirely out of one single

To 3D print a shoe, you'll need to start by deciding what style of shoe you want to create. Once you have a design in mind, you can use a 3D modeling program to create a digital file of your shoe. Then, you can use a 3D printer to turn your digital design into a physical shoe.

These 3D printed shoes are made for walking 3D Printing Blog i

November 28, 2023 Randy Collins 3D Printing Ideas The concept of 3D printed shoes has been rapidly gaining traction in the footwear industry. As consumers seek more personalized and sustainable options, these shoes offer an innovative solution.

Adidas Plans to Produce 100,000 Pairs of 3DPrinted Shoes by 2018

3D printing shoes allows companies like Reebok and Nike to design more complex footwear using materials previously thought unfeasible. Allowing for complete customization, the best 3D printed shoes come from companies like Zellerfeld and FUSED, which can cater to any customer regardless of foot size or tastes.

Adidas 3D printed Shoes Customised For Each Individual's Feet

FUSED footwear started in May 2017, when we put together our first 3D printer. We've since made several different designs, and have weartested our shoes extensively. as one piece. They can be worn daily, just like regular shoes. Our shoes are also fully recyclable, so when they've worn out, please return them to us for a 20% discount.

2016 3D Printed Shoes Highlights YouTube

Fabric strips Smartphone camera 3D modeling software (preferably 3DS Max) A 3D printer You'll want to follow the directions for (fun!) making the cast of the innards of your shoe and then.

Adidas' latest 3Dprinted shoe puts mass production within sight

Conclusion. 3D printing is reshaping the landscape of shoe manufacturing from the ground up. The customization it offers, coupled with increased efficiency and sustainability, marks a paradigm shift in an industry steeped in tradition. As technology continues to advance, the marriage of innovation and craftsmanship in 3D printed shoes is set to.

Under Armour 3D Printed Sneaker Architech Sole Collector

A running shoe can now be partially created with 3D printing technology. Actually, the midsoles of running shoes are particularly suitable for 3D printing. Big shoe manufacturers are using additive manufacturing. For example, brands like Adidas, Nike, New Balance and Under Armor have already printed sneakers.